Ammonia

An industrial chemical used as the base feedstock for hundreds of end-market products from textiles to plastics, healthcare to electronics, as well as an ideal fuel for power generation.

What is ammonia?

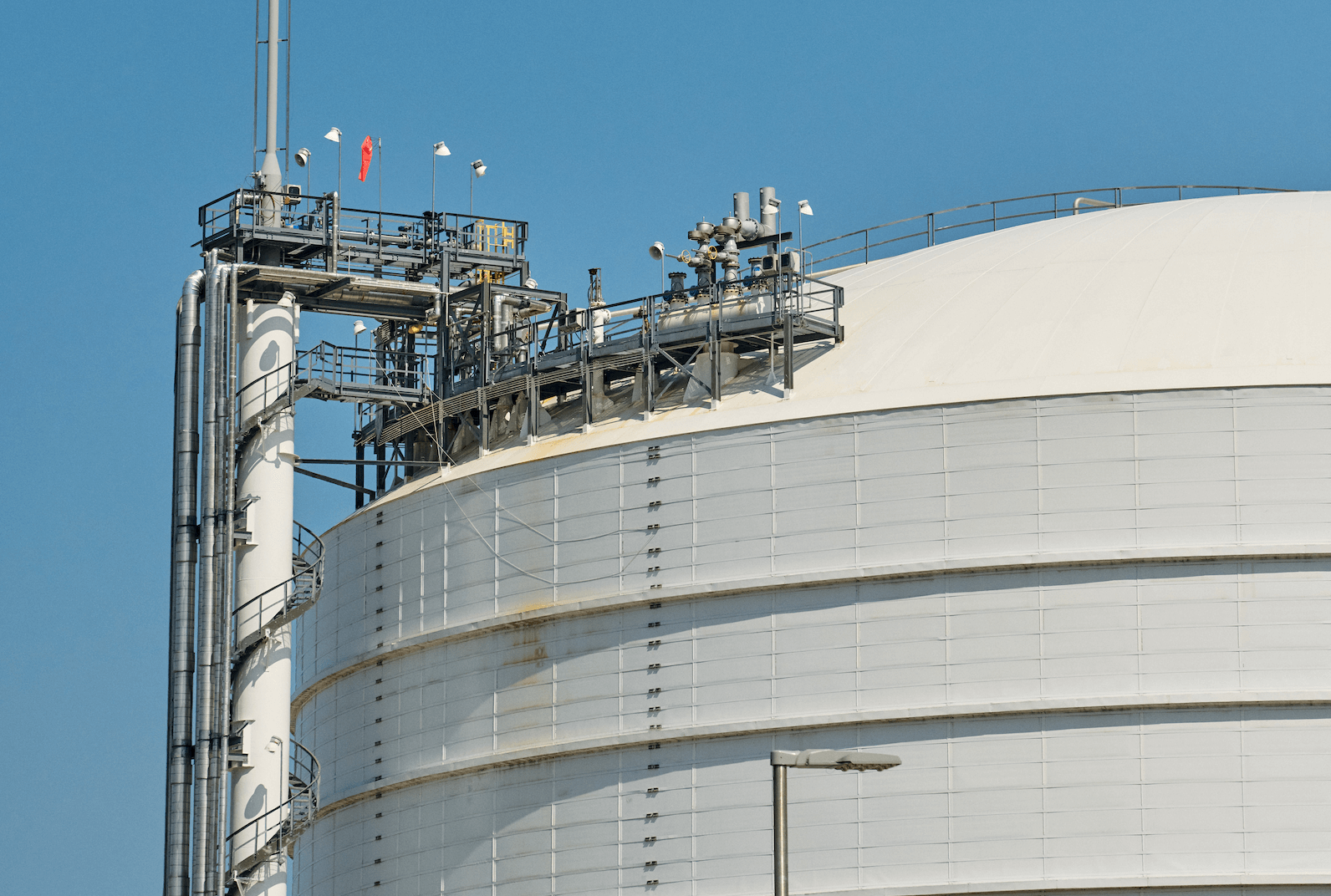

Ammonia, produced in anhydrous form (without water), is a colorless gas that is a building block for industrial chemicals and nitrogen fertilizers, and can be applied as a direct fertilizer. Ammonia is the highest energy density non-hydrocarbon product.

Our bio- and green ammonia are ISCC PLUS certified. We are the first ammonia producer in Europe to use bio-methane to produce and sell green ammonia. The sustainable product and mass balance system is ISCC PLUS certified and can be used to produce green downstream products. The GHG footprint is at least 50% lower compared to grey ammonia and can be decarbonized further depending on customer requirements.

OCI is one of the only producers today of renewable (green) ammonia from biogas. Our bio- and green ammonia are ISCC PLUS certified. We are the first ammonia producer in Europe to use bio-methane to produce and sell green ammonia. The sustainable product and mass balance system is ISCC PLUS certified and can be used to produce green downstream products. The GHG footprint is at least 50% lower compared to grey ammonia and can be decarbonized further depending on customer requirements.

Our bio- and green ammonia are ISCC PLUS certified. We are the first ammonia producer in Europe to use bio-methane to produce and sell green ammonia. The sustainable product and mass balance system is ISCC PLUS certified and can be used to produce green downstream products. The GHG footprint is at least 50% lower compared to grey ammonia and can be decarbonized further depending on customer requirements.

OCI is one of the only producers today of renewable (green) ammonia from biogas. Our bio- and green ammonia are ISCC PLUS certified. We are the first ammonia producer in Europe to use bio-methane to produce and sell green ammonia. The sustainable product and mass balance system is ISCC PLUS certified and can be used to produce green downstream products. The GHG footprint is at least 50% lower compared to grey ammonia and can be decarbonized further depending on customer requirements.

Ammonia applications

Agriculture

About 80% of the world’s current ammonia supply is used in agriculture as direct application fertilizer or as a building block for the creation of liquid or granulated fertilizers.

Industrial feedstock for chemical processes

Used in manufacturing processes including as a catalyst in chemical processes.

Power

Ammonia can be co-fired with coal in existing plants to reduce the use of coal in current power infrastructure.

Marine

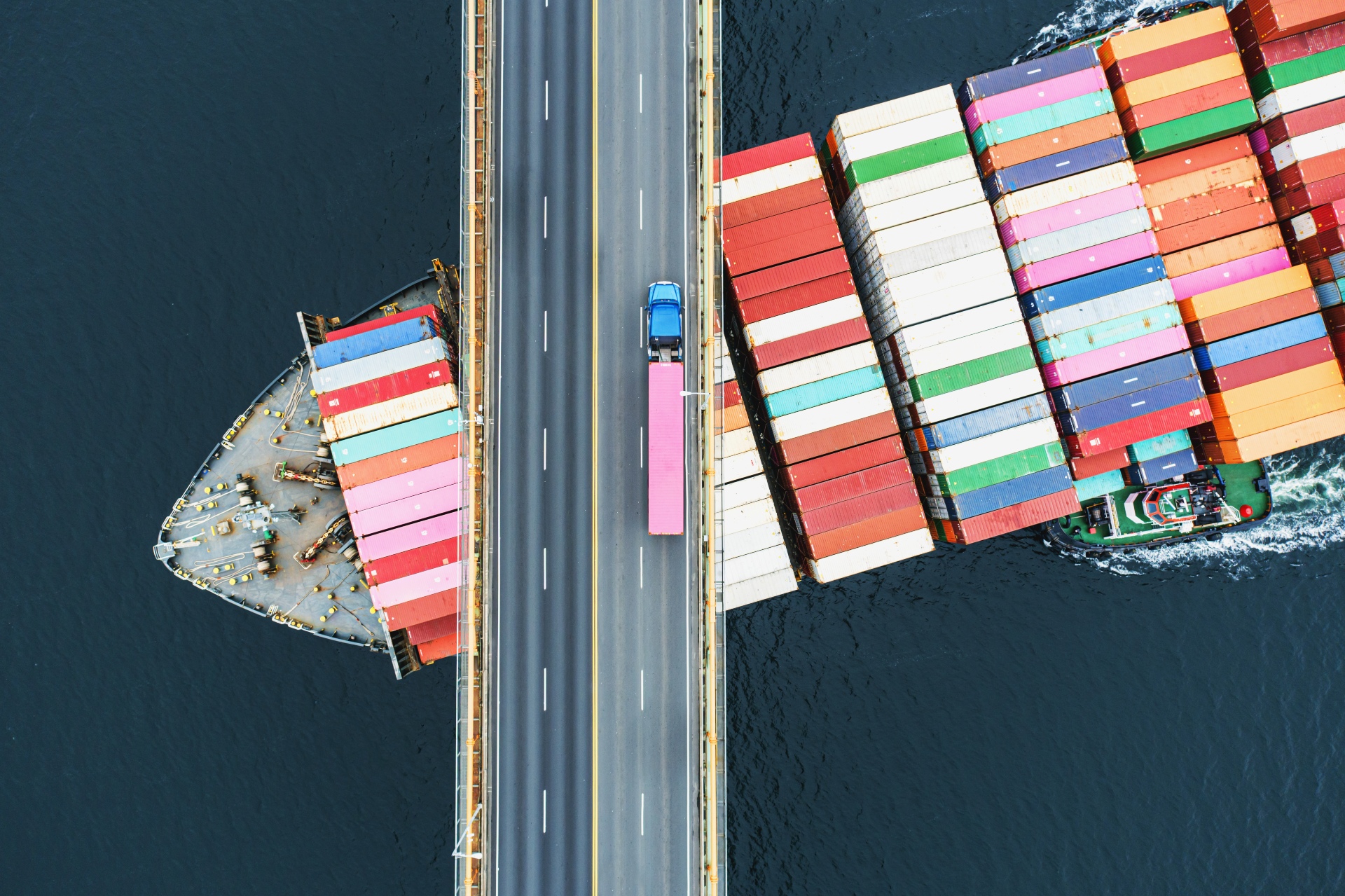

As a clean-burning liquid fuel, ammonia, is a key cleaner fuel option for the shipping industry.

Hydrogen carrier

Ammonia is easier to store and transport than hydrogen, meaning it can be used to store and transport hydrogen before being ‘cracked’ to release the hydrogen at the desired time and location.

Our ammonia solutions

We’re a global producer and distributor of renewable, low carbon and conventional (grey) ammonia.

Renewable ammonia - produced from feedstocks

There are two types of renewable ammonia that can be produced by OCI today:

- Bio-ammonia: can either be produced by using biogas instead of natural gas in existing facilities or from biogenic fraction of gasification of municipal solid and biomass waste.

- Green ammonia: can be produced from hydrogen from electrolysis based on renewable electricity.

Low carbon ammonia

Ammonia produced from virgin fossil with lower carbon intensity (CI) than grey ammonia and industry average emission or from recycled fossil feedstocks.

- Blue ammonia: can be produced with lower carbon hydrogen from natural gas with CCS that can achieve CI reduction of at least 60% compared to industry average (2.6 tCO2e/t ammonia) on a cradle to gate scope.

- Circular ammonia: can be produced from recycled fossil hydrogen from gasification of municipal solid waste.

- Low carbon ammonia: is produced using hydrogen with lower CI compared to industry average. The sources can include by-product hydrogen from steam crackers or chlor-alkali.